Feature Description:

1、Without plate making and washing machine, CMYK four primary color jet printing mode is adopted, which is convenient, low-carbon and environmental friendly.

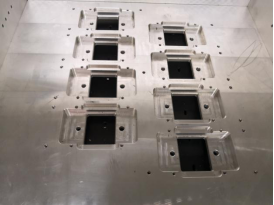

2、The nozzle is fixed by one button, and it can be installed and used immediately without adjustment.

3、New nozzle cleaning mode, automatic cleaning, no need to adjust frequently, more ink saving, more stable.

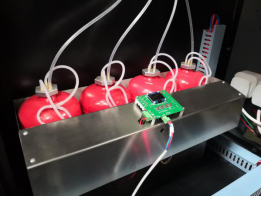

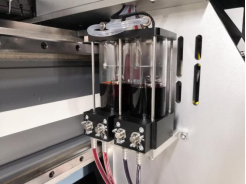

4、Brand new automatic industrial ink supply system, visible two-stage ink cartridge, negative pressure control, ink more stable, better effect.

5、 The whole machine adopts independent PLC control system with high reliability, strong anti-interference ability and good man-machine interaction.

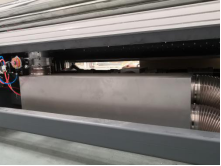

6、The use of larger torque servo motor with high precision cycloid pin gear reducer, higher precision, faster speed, more stable performance.

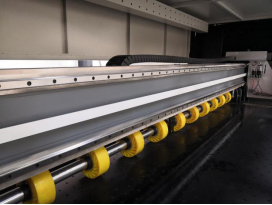

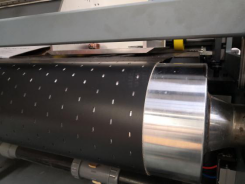

7:、The power roller with high precision outer circle grinding is adopted to drive the belt transmission and drive more accurately.

High strength rail beam, overall processing, silent guide rail fit flatness error is less than 0.05mm, printing plane is more stable and precision is higher.

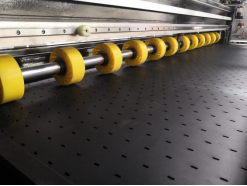

8、The whole process of paper feeding is guided by suction and absorption, assisted by sun wheel and pressure roller to ensure the smoothness of paper and better printing effect. The air suction of the printing area is divided into six areas, with the adjustment range of 1200-2500mm. Meet most paper widths.

9、The suction system adopts two 3KW large volume fans, with strong wind force, stable and reliable.

10、 Front automatic paper feeding, needle light control, stable and fast paper feeding. It can print multiple copies and multiple sheets at the same time. It is the first in China to print multiple copies and multiple sheets. It has high stability and faster printing speed and capacity.

11、 The paper feeding Department has its own telescopic paper carrier, which is convenient for the transportation of long paper board and large paper board. The long paper board of about 2m can be placed normally

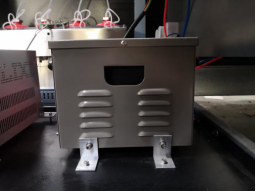

12、 Voltage regulator with 380V transformer

project | detailed description |

Nozzle | 8 sets of high precision sprinklers (using original Japanese Epson sprinklers) |

The distance between the nozzle and the medium is 1 mm-2 mm. |

The width of each pass is about 271 mm. |

|

Automatic ink supply |

Ink | Water based ink |

colour | C M Y K |

Printing speed | pattern | PASS | the measure of area |

high-precision | 1PASS | 500m 2/h |

high-speed | 2PASS | 250m 2/h |

Print width | 2500mm |

Print length range | unlimited |

Paper thickness | 3-20 mm (more than 20 mm can be customized separately, and less than 2.5 mm can be manually placed) |

Automatic paper thickness measurement, ultra thin alarm prediction. |

control mode | PLC |

Print resolution | 720*600 360*600 |

Ink drying speed | The drying rate of other materials varies with the material; |

Software | Yiheng special printing software and RIP software |

work environment | Room temperature 10-35 degrees, humidity 20-70% |

power | About 10kW power supply: AC380 ± 10%, 50-60Hz. |

Overall size and weight | Length × width × height 2220 × 4750 × 1730mm weight: about 4500kg. |